If you're looking for a durable fall protection system that won't damage your rooftop, non-penetrating guardrail systems are ideal. Non-penetrating fall protection systems for roofs aren't designed to be temporary, but since it's not physically attached to the roof it can be moved or relocated if needed. Instead of fasteners or bolts anchoring the guardrails down, the railings are held down by cast iron bases.

There are several different types of non-penetrating guardrail systems, but they all have one thing in common: they provide OSHA-approved rooftop fall protection that won't damage the integrity of the structure or void any roof warranties.

The Integrity of Your Roof Is Preserved. With non-penetrating systems, your rooftop will not be affected by thermal expansion and contraction, which can cause roof damage. The system also eliminates liability for long-term maintenance due to leaks.

OSHA Compliance. OSHA regulations require that employers provide fall protection to all of their employees. Most non-penetrating fall protection systems for roofs are in full compliance with OSHA requirements, so you don’t have to worry about the safety of your workers.

They’re Easy to Install. There's no need to penetrate the roof, which means the installation time for non-penetrating systems is very quick. This will save you a lot of time and costly installation fees. The main components simply click into place, leaving you and your workers with more time to do more important tasks.

Safe and Strong. Non-penetrating guardrails are reliable and stable, and provide superior safety for your workers.

Flexibility. Extremely versatile, fall protection systems for roofs can be customized to fit your exact needs. Different guardrails and toe plates can be added as necessary.

They Can Be Moved. Non-penetrating guardrail systems can be broken down and re-assembled very quickly.

Slip Resistance. Optional base plates can be installed with non-slip pads. These pads will keep the base from slipping on any smooth surfaces such as metal or smooth concrete. They also help provide a cushion on rubber materials.

Corrosion Resistance. Powder Coated Paint or Hot Dipped Galvanized provides weather resistance, no matter what the elements bring.

Customizable. Custom engineered safety guardrails are available if none of the non-penetrating safety railing systems will fit your needs.

Peace of Mind. Installing non-penetrating fall protection systems will ensure the roof you're working on will not be damaged. Also, your workers will stay safe and your company will be up to all OSHA safety codes.

Bases are the backbone of non-penetrating guardrail systems. They provide a set anchoring mechanism for the rails to meet OSHA's minimum requirement of being able to withstand a load of 200 pounds. You can tell when a base is right for your rooftop when it:

Here are the options to consider when choosing non-penetrable guardrails to protect the integrity of your rooftop:

Classic guardrails are great for any type of surface and ensure maximum safety.

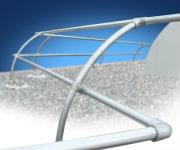

These rails provide great safety and trendy curves to accentuate a building's architecture.

These are similar to straight guardrails, but collapsible for when you want to easily hide the guardrails and improve the appearance of your building. The safety rails only have to be visible when needed.

Customized Safety Gate Option

A gate can be installed to make it easy for workers to move between sections divided off by a guardrail.

As you are likely aware, the risk of unprotected roof edges can have extremely negative consequences for your employees as well as for your company. By using non-penetrating fall protection systems for roofs you can keep your workers safe, your business covered, and the structure of your building intact.

Find a non-penetrating fall protection system for your rooftop today – it’s one of the smartest moves your company can make.