OSHA safety standards, especially for roof fall protection, can be a source of confusion for many industrial companies. Two OSHA standards can apply – 29 CFR 1910, which governs “general industry” safety standards and 29 CFR 1926, which governs construction sites specifically. The OSHA general industry standards exclude construction (as well as agriculture and marine industries, which also have their own standards), but both standards can sometimes apply to the same worksite at different times. Determining which one you should adhere to can be a challenge.

Generally speaking, the 1926 standards have some regulations that are quite different from those covered in the 1910 standards, despite the fact that they address similar safety concerns. There are also regulations in the 1926 standards that are simply not included in the 1910 standards.

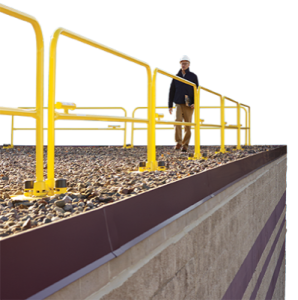

In terms of fall protection systems, the most significant difference lies in the elevation height of the leading edge where protection is required. The general industry 1910 standards state that an “employer must ensure that each employee on a walking-working surface with an unprotected side or edge that is 4 feet (1.2 m) or more above a lower level is protected from falling” while the 1926 construction standards specify that “each employee on a walking/working surface 6 feet (1.8 m) or more above a lower level where leading edges are under construction, but who is not engaged in the leading edge work, shall be protected from falling by a guardrail system.” This does not necessarily mean that construction sites shouldn’t provide fall protection for distances between four and six feet, but it does mean that a company may not be cited for failing to provide it in that range.

In regards specifically to roof fall protection, the 1910 standard specifies for low-slope roofs that when “work is performed less than 6 feet (1.6 m) from the roof edge, the employer must ensure each employee is protected from falling by a guardrail system, safety net system, travel restraint system, or personal fall arrest system.” The 1926 standard doesn’t make specific mention to distance from roof edge, but again states that for roofing work on low-slope roofs “with unprotected sides and edges 6 feet (1.8 m) or more above lower levels shall be protected from falling by guardrail systems, safety net systems, personal fall arrest systems,” or a combination of those systems.

When is Construction “Construction”

When is Construction “Construction”The true complexity comes in determining when each standard applies. Construction sites are usually obvious – the new construction of a building, for example. However, renovations and repairs may be considered construction as well, while routine maintenance generally is not.

There are no hard and fast guidelines as to whether OSHA will consider any given activity to be “construction.” In fact, many activities fall under the general maintenance category, especially:

Major repairs, however, are likely to be considered construction and will require the use of guardrails at the 1926 standard, at least. For example, replacing a rooftop convector system for building-wide air conditioning, which involves the use of a crane, should be considered construction. In this situation guardrails should be used wherever a potential fall may occur, whether it be the rooftop edge or the newly created hole where the air conditioning unit once stood. OSHA also considers painting and decorating to be construction work as well. However, construction work does not specifically include the manufacturing or furnishing of materials.

As you can see, determining what constitutes construction is not always easy. Jobs need to be considered on a case by case basis before you begin them – site managers must review the guidelines and carefully consider each before deciding on a standard to follow. Problems can occur when the site manager is following one set of standards for roof fall protection while OSHA decides to apply the other.

The Safest Course

The Safest CourseThe safest course of action is to follow the most conservative standard. Even if you are fairly certain that OSHA would categorize your site as a construction site, you should use fall protection systems and guardrails at the tighter four foot standard as much as possible. If you are using a crane or hoist, you should apply the 1926 roof fall protection standards even if the work is relatively routine.

Site managers need to study the standards carefully and be aware of exactly when, and to what, they apply. Each and every case is different, and a site manager needs to make a reasoned decision about what fall protection systems and other precautions should be taken on site, through all the different phases of a project. They also need to take into account whether multiple contractors are working on site and ensure that safety is coordinated across the entire group. The responsibility for maintaining the OSHA required safety standards will always fall on the host employer when multiple contractors are working on a site.

When possible, the most conservative standard should always be followed to reduce the risk of incurring an OSHA penalty. As a rule, site managers should make sure they are familiar with both the 1910 and 1926 regulations, and use above and beyond vigilance in providing the proper fall protection for all people on the worksite.